May 12th, 2022

9minute read

The postman handed it to me as if it were a broom.

I tore a fingernail on the brown wrap over the long cardboard box.

Inside, a spanking-new pump-action shotgun gleamed from folds of oiled paper.

In the mid-60s, crimped plastic was replacing card-stock over-shot wads and waxed paper hulls.

But the smoke curling from those first empties had an addicting aroma plastic would never match.

That heady scent came to me again the other day.

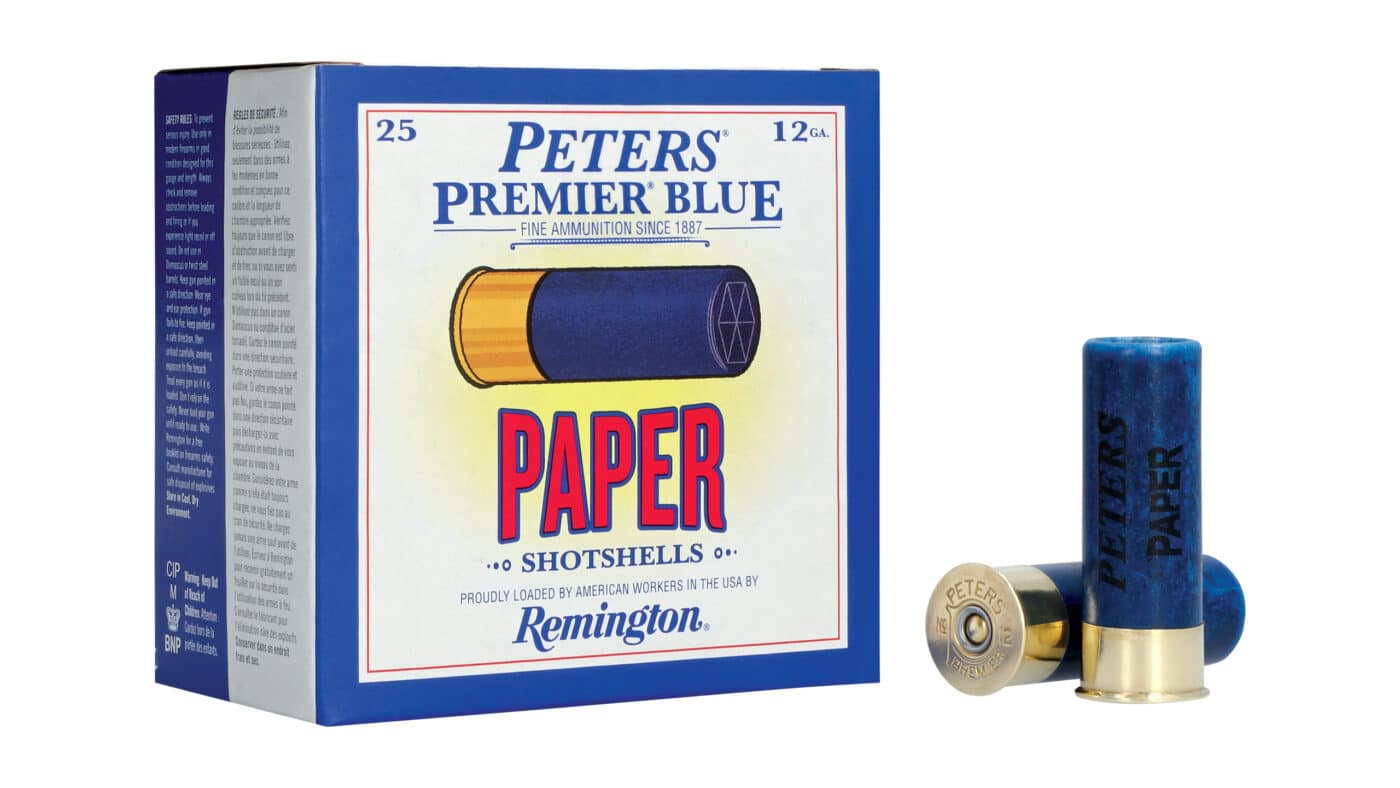

The shotshells werent old, but crisp new Peters loads, with the waxed blue paper of decades past.

Lead dropped through sieves atop an 11-story tower forms shot for standard Remington loads.

Of course, the company also offers lead-free and special shotshells.

These are special, Jon assured me.

We looked hard for paper that matched exactly the color of the original Peters Premier Blue.

The shot is hard, with 5 percent antimony.

Heads are brass, not plated steel.

Its used in top-shelf target loads.

Besides, its traditional.

This load, whatever the brand, ranks among the most popular with trap shooters.

Its also a hit with hunters after ruffed grouse, woodcock, pigeons, doves and quail.

Not just the material and printing, but the finish.

Theres more to an attractive box than most shooters think!

Producing paper shotshells is a complex process too, and more time-consuming than is the case with plastic hulls.

Skiving the paper is the first step.

During WWI among British troops, skiving came to mean avoiding work.

As slang, that definition persists.

But skiving as applied to materials is a shaving process, to taper or reduce thickness.

A cobbler makes leather more flexible by skiving it.

Colored shotshell paper comes to the factory in huge rolls, each of which will make 25,000 hulls.

It is skived to taper and finish edges of sheets before theyre rolled and glued into tubes.

These dry and cure in a heat-treatment room.

Initial skiving takes a day per batch, Jon told me.

Then the paper is rolled and glued and kept for a day under heat to cure.

Figure another day for conditioning.

Then the 12 tubes are cut into four 234 tubes and impregnated with wax to repel water.

The tubes are conditioned for another 10 days before they go to the heading machine.

Start to finish, a paper shotshell takes 14 days to make.

He also added, it requires more employee time and factory space than a plastic shell.

Producing your own paper shotshells is about as practical as making your own light-bulbs.

For all that, however, paper shells dont last as long as plastic.

A couple of loadings, said Jon, before youll find the occasional leak around a battery cup.

Wound paper base wads dont seal as well as do plastic.

Paper is easier to crimp but of course, those creases wear out sooner.

In papers favor: Competitive shooters say recoil is less punishing.

And theres that smoking-waxed-paper smell … .

(If legend is to be believed, the term shotgun originated in Kentucky in 1776.)

Leet Co. of Springfield, Massachusetts, patented a paper shotshell in 1869.

The first paper shells were sold, empty, in boxes of 100.

Shooters were accustomed to handling components separately and had no reason to expect factory loads.

After all, the Civil War had just been fought with caplock rifles.

Shooters were soon clamoring for loaded paper shells.

(The only holdouts were waterfowlers, who would stay with brass shells until paper got wax waterproofing.)

Alas, the components that fed Chamberlins loader came from two established ammunition companies.

These firms tooled up to serve the booming market and cut ties with Chamberlin.

By 1900 he was out of business.

Remington bought what remained of Chamberlin Cartridge Co. in 1933.

His loaded shotshells were the first sold in boxes of 25.

(Early on, these were called quarter boxes and shipped 20 to a wooden crate.)

And his modestly priced ammunition weaned many shotgunners from loading their own.

The Foundation

Brothers Gershom M. and O.E.

Peters formed Peters Cartridge Co. in 1887.

Gershom was son-in-law to J.W.

But Peters hiked production rates with steam power and improved the machinery.

No longer were workers required to put components in hulls by hand.

Initially, Peters bought paper hulls from UMC, U.S. Cartridge and Winchester.

But AB&Cs tooling was later sold to Peters.

By 1891 Peters was making its own paper hulls, under the Prize label.

Four years later it built a shot tower, and was soon producing wads and primers as well.

With propellant from King Powder, it was a self-contained company.

Advertising its ammunition with colorful images on the boxes set it apart from the competition.

By the early 1900s, Peters had a range of shotshells.

Semi-smokeless powder in its Referee loads offered velocity equaling the best nitro powders, with low breech pressure.

Demand for ammunition in Europe prospered the industry stateside until the armistice in 1918.

Defunct military contracts and Depression capped that demand.

During the 1920s and into the 30s, Peters investments in its factory failed to turn loss to profit.

The roller-coaster market in small-arms ammunition hit another high during WWII.

Predictably, demand again plunged in its wake.

For ease of manufacture, almost all shotshells now, paper and plastic, have folded crimps.

But some 19th-century practices endure.

High brass and low brass hulls, for example.

Bigger powder charges required taller case heads than did target or light upland loads.

Double-base (nitrocellulose and nitroglycerine) smokeless powder made high brass unnecessary, as propellant volume was much reduced.

Powder columns of even stiff waterfowl loads were short enough to match low or mid-height brass.

Tradition matters, smiled Jon Langenfeld.

Conclusion

He rang off, then.

It was quitting time in Lonoke, Arkansas.

But most of the afternoon remained here in the Pacific Northwest.

a disk rocketed from the hand-trap.Bang!It shattered.

Instead of jacking the empty free, I eased the slide open and let it tumble into my hand.

I brought it up and drew deep of the lazy curl of smoke from its mouth.

Alice had her arm cocked, another bird in the clamp.

Not yet, I said.

Go to forum thread