Ill admit that I had never really thought about it.

Moving Forward

Remington Ammunition was purchased out of bankruptcy last fall.

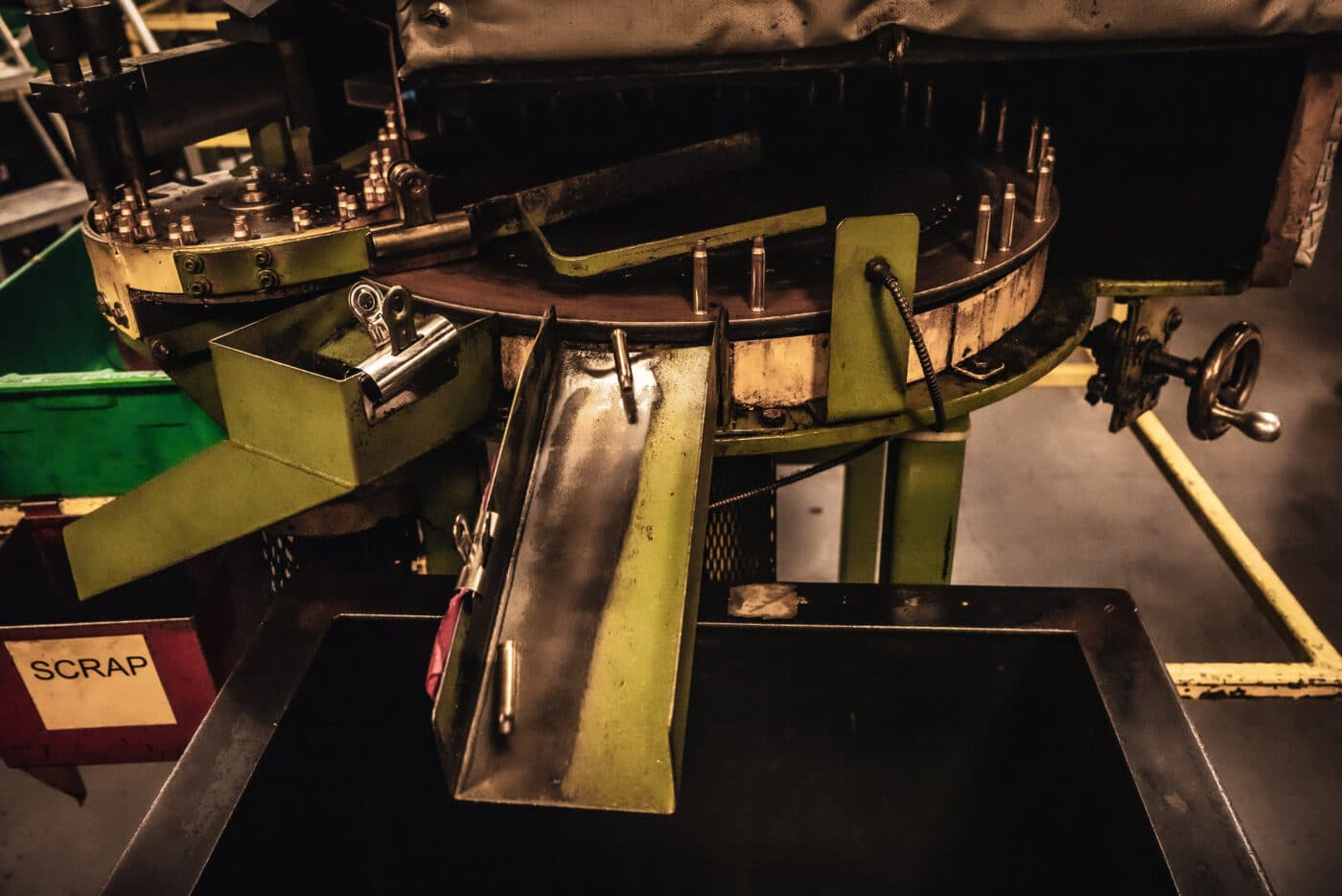

To say the state-of-the-art manufacturing capabilities at the plant were impressive would be an understatement.

Also, the mountains of raw materials that are turned into ammunition are just incredible to see.

Let me tell you, having seen it in person, its stunning and truly impressive.

The Shot Towers optimal height is a full 11 stories tall.

You reach the tower from an original freight elevator that takes you up to the top.

Here, a very large kiln holding tank of molten lead is housed.

Lead naturally becomes a sphere as it falls and cools for the drop.

The next step for the lead shot is a series of glass tables the shot runs down.

This method is used to separate out odd sizes and defective pieces.

Below these containers is another floor where workers dispense the amount of shot needed for loading shells.

Remington makes every single component of their shotgun shells at the facility.

Shotgun shell hulls start as small pellets of clear plastic mixed with whatever color pellets the shell will be.

Rimfire ammunition is also produced at the facility.

Millions of rounds a year come out of the rimfire machines.

I could not be more happy to see that the Big Green is back!

Go to forum thread

Remington