Everyone that we encountered was obsessed with creating the best products for the end-user, period.

The optic is checked to see if the reticles line up together perfectly.

To the right of that technician is a steel post with a rubber top.

Nightforce Optics combines state-of-the-art manufacturing with a hands-on human element to ensure reliable and capable products for the field.

They then check to see if the reticle is still aligned.

They repeat this process on all four sides as well as the front and rear of the scope.

Talk about putting your money where your mouth is.

The Nightforce Optics manufacturing facility is located in Orofino, Idaho. Without a doubt, the area is absolutely beautiful.

The scope is then frozen to -80F and then heated to 160F within a one-hour period.

Every lens in every scope is matched and aligned by hand, yielding the highest levels of optical performance.

These little details make a Nightforce one of the best scopes in the world.

Nightforce Optics is a company with employees who are extremely passionate about their work.

The ATACR line is their premium offering created for military and law enforcement professionals.

The NX8 line boasts an 8X zoom range that is sharp at every setting.

This is achieved by using premium materials and the latest optical technology.

Nightforce Optics uses the best materials and equipment available to create the housings, turrets and other pieces of their lines of optics.

The NXS line are workhorses that have been building the Nightforce reputation for decades and keep on performing.

In Australia, rabbits, foxes and pigs are considered varmints that can wreak havoc on a landowners crops.

Therefore, the best time to hunt these creatures was when they were most active, at night.

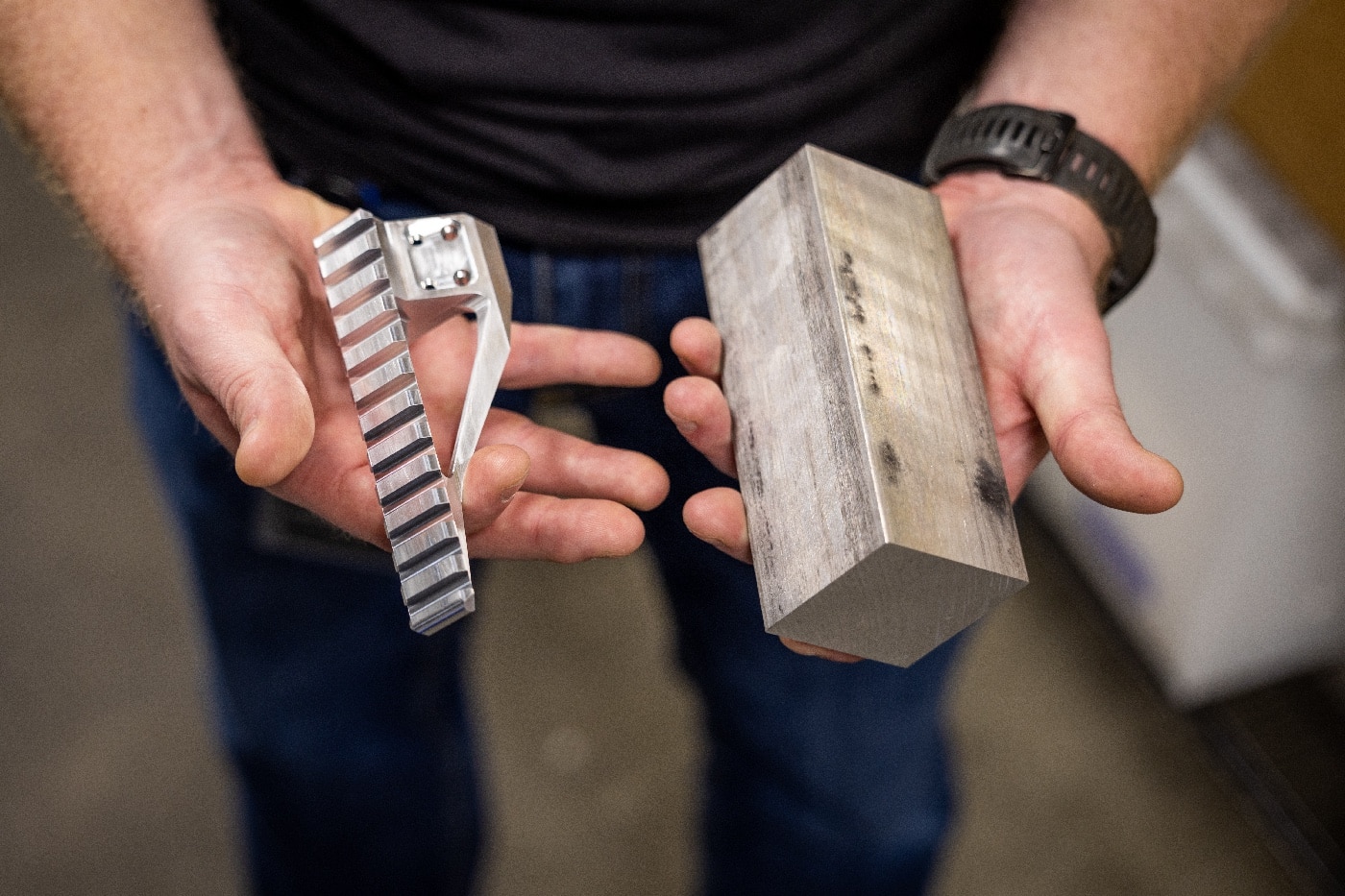

The technicians at Nightforce Optics can skillfully turn a chunk of aluminum into a solid scope mount.

He began development on a rifle light that could spot animals out to 400 yards.

He ordered 500 scopes, and they were a huge success.

The company then set up a Seattle branch to focus on making scopes for the U.S. market.

The Nightforce Optics team undertake significant testing of each riflescope prior to it being packaged and shipped.

In 1990, the company was renamed Nightforce.

Dennis now operates his lighting products under Lightforce, while the rifle optics remain under the name Nightforce.

In 1998, the company moved from Seattle to Orofino where they currently reside.

Nightforce scope tubes are made from solid bar stock 6061-T6 aluminum that is two to three times thicker than most other riflescopes. This allows for greater thermal stability.

Nightforce continues to provide the U.S. Military with optics that give our soldiers the edge in combat.

With Nightforce, you get exactly what you pay for perfection.

Go to forum thread

Nightforce

The company’s meticulous attention to detail and rugged build quality has not gone unnoticed. In 2010, Nightforce Optics won a contract with USSOCOM.

These two trays of Nightforce scopes represent untold hours of design, development, manufacturing and QC checks.

Once the scopes are assembled and successfully pass all testing and QC checks, they will be readied for shipping.