I was fortunate to recently have had the privilege of touring the Chapman Manufacturing facility.

Bill, an engineer bought the business from Mr. Chapman.

Thus, Tracy is only one or two steps removed from the inventor.

Chapman Manufacturing, an extremely well-known name in gunsmithing tools, first opened for business nearly 90 years ago.

Joel is familiar with all aspects of marketing, manufacturing, packing and shipping.

The Foundation

The company has a strong Buy American ethos.

The bits and extensions are made from USA tool steel.

Shown is part of Chapman Manufacturing’s machine shop where many of the company’s tools are made.

Even the plastic cases, cutting oils and packaging materials are made in America.

This alone is a full-time job.

The chips are sold off to a steel recycler to be remade into other steel products.

Part of the company’s collection of its tools is the above Chapman CM 1400 tool kit from World War II.

Even the outside of the Chapman factory is environmentally friendly.

They have a pollinator garden right outside the shipping and receiving door with all sorts of plants.

Older Chapman tool sets came in a red box that resembled a jewelry box.

Chapman Manufacturing Wood Sets are heirloom-quality tool kits with wooden cases. Image: Chapman Manufacturing

Newer sets were sold in a yellow box.

Chapman uses its own tools to keep the plants machinery running at peak efficiency.

Best of the Best?

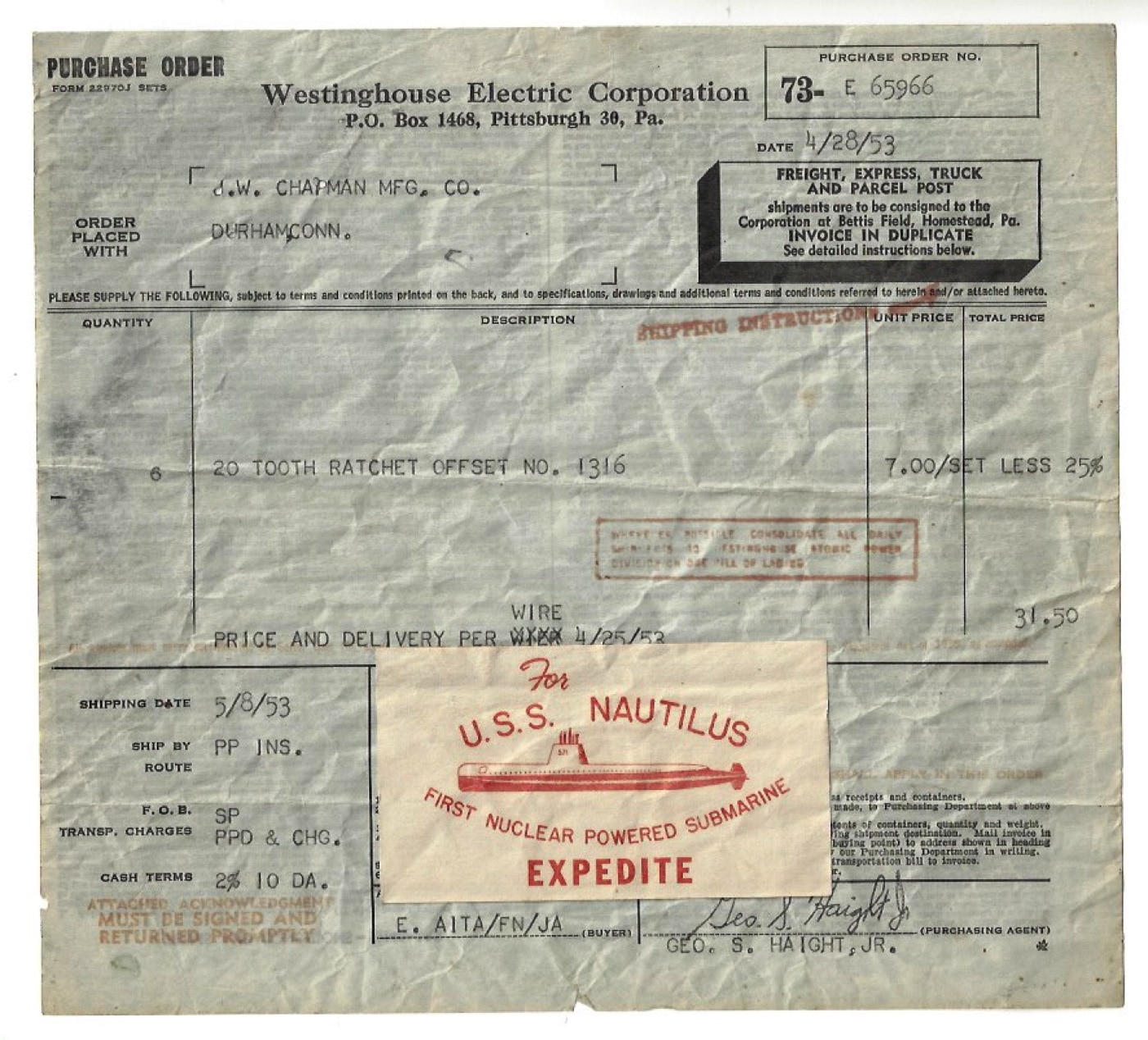

Chapman Manufacturing provided tool sets for the USSNautilus(SSN-571), the first nuclear-powered submarine. Image: Chapman Manufacturing

The bits are engineered to breakbeforethe fasteners that they are sized to turn.

On an older firearm, for which spare parts are hard to find, this matters a lot.

Chapman bits and extensions are black oxide coated to reduce the chances of rusting.

Sitting on these racks are bars of U.S.-made steel that will be fed into CNC machines to make Chapman Tools.

The coating does not increase the size of the bit in other words, Chapman bits properly fit fasteners.

Another unique Chapman feature is a ball detent to keep the bit from dropping out of the driver.

In my opinion, the ball detent is superior to a magnet which can interfere with sensitive electronic equipment.

Newly made Chapman tools come off the CNC machine and are ready for the next step in the manufacturing process.

The ends of the bits are knurled, which makes it easy to tighten fasteners with just fingertip pressure.

For a long time, the standard Chapman extension was 3 5/8 inches long.

The company now offers two and six inch extensions, (I prefer the two inch).

As I explained above, there is little to no waste at the Chapman factory.

Conclusion

Chapman Manufacturing is, in every sense, a family business.

Tracys husband is an accountant and takes care of the taxes and payroll.

Joel handles regulatory compliance and sales.

I have used Chapman tools for over 30 years and have never been disappointed.

I have no reservations about recommending them toThe Armory Lifereaders.

Go to forum thread