Home ImprovementTools

An air compressor is one workhorse you would want to have at your disposal.

There are plenty of things you’ve got the option to do with it.

Its no surprise that this versatile and useful rig is integral in various industries.

How Do Air Compressors Work?

An air compressor operates by forcing air into a container before pressurizing it.

The air is then forced through an opening where the pressure increases.

you might liken the energy released by an air compressor to the air from a balloon.

When the compressed air in the balloon is released, it can be used as energy.

In the past, air compressors were solely used in industrial shops.

They were fixtures in gas stations and manufacturing plants.

But these days, more and more people use air compressors at home.

They store air compressors in their basements and garages.

There are two principles applied in air compressors.

These are positive displacement compression and dynamic displacement compression.

Understanding the differences between the two can help you find the right air compressor for your needs.

Most air compressors for home use positive displacement compression.

Its versatile, reliable, and practical, which has made it adopted by various industries.

Positive displacement compressors work with a constant flow of air regardless of the pressure.

The performance of the compressor is hinged on external conditions like changes in inlet temperatures.

In dynamic compressors, the air is pulled between the blades on a speedily rotating compression impeller.

The gas is subsequently discharged through a diffuser, wherein the kinetic energy is altered into static pressure.

Dynamic compressors are fondly called turbocompressors due to their capability to produce high horsepower.

Examples of air compressors that fall under dynamic compression are axial compressors and radial or centrifugal compressors.

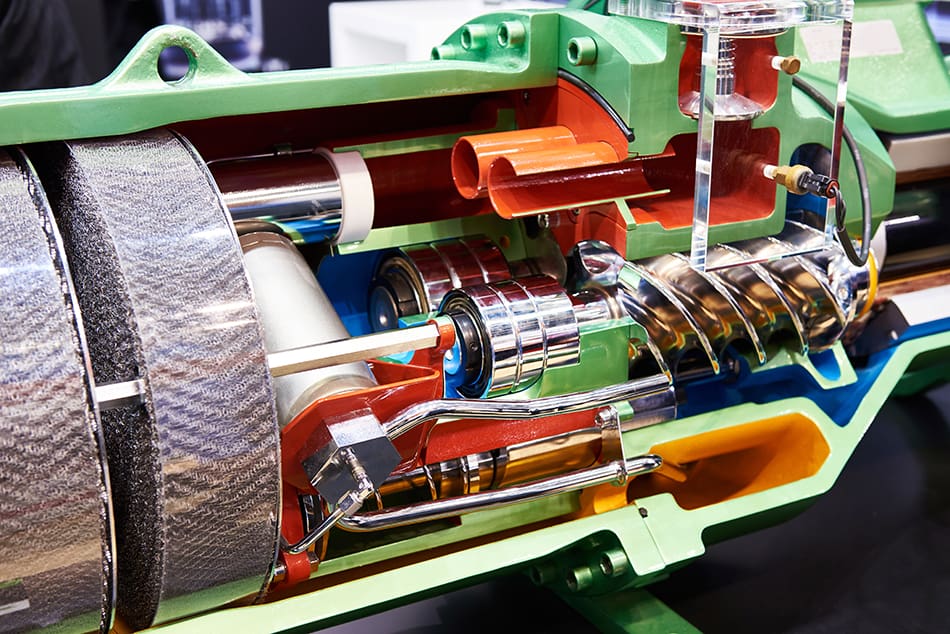

Most rotary screw air compressors come with an internal cooling system, which makes them built for continuous use.

These are typically large machines that are found in large and small factories.

But dont be surprised to see one, too, in bigger garages and workshops.

A rotary screw compressor works by trapping air between two interconnected rotors that turn in opposite directions.

It then reduces the volume of the trapped air while it moves down through the rotors.

The reduction in volume leads to compressed air, which you could use for various applications.

While a rotary screw compressor sounds enticing to buy, its not something thats built for everyone.

In shopping for a rotary screw air compressor, there are some things it’s crucial that you consider.

It also helps to buy a rotary screw compressor with integrated filters and air dryers.

You should also consider the electrical phase of your requirements, something that your electrician can help you determine.

Finally, buy a rotary screw air processor from a reputable manufacturer.

Some of the better-known air compressor brands are Belaire, Ingersoll Rand, and Chicago Pneumatic.

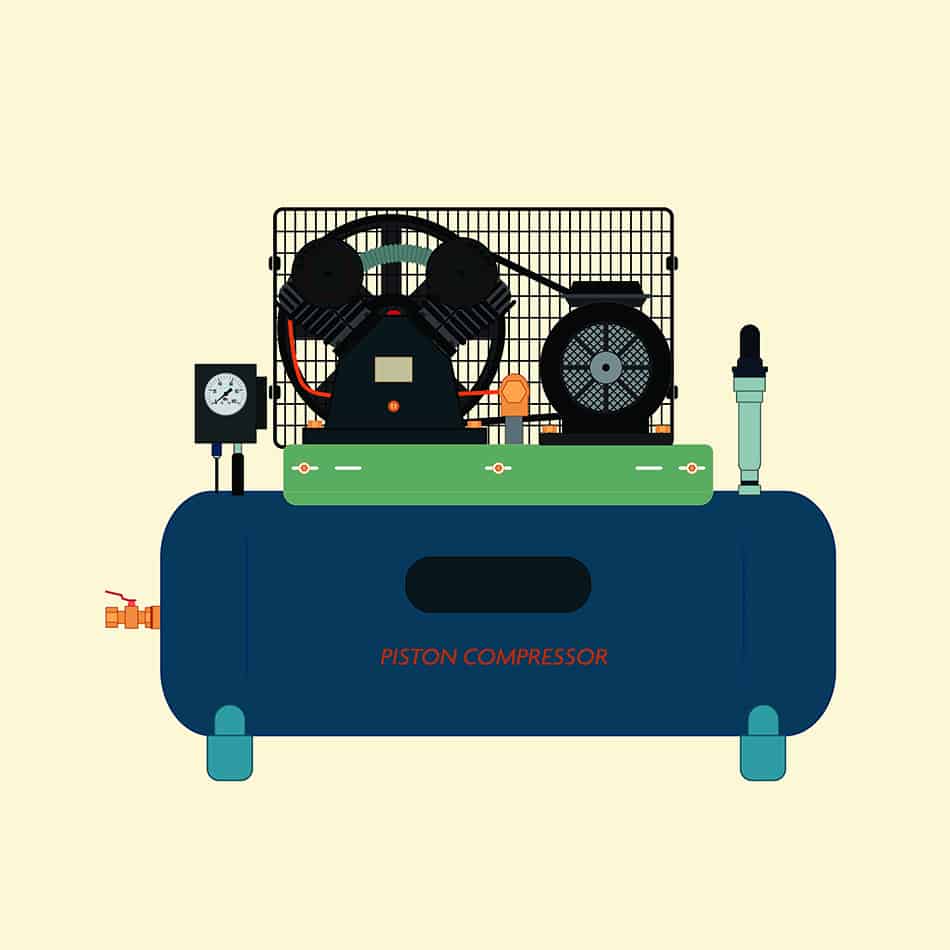

The piston goes back and forth in a reciprocal movement, hence its name.

The design of the compressor is similar to that of an internal combustion engine.

It has three types: single-stage, two-stage, and duplex units.

It is then sent to a storage tank.

On the other hand, a two-stage reciprocating piston compressor features an extra step.

The air is compressed by a smaller piston, thus the name two-stage compressor.

Lastly, the duplex types are practically two separate compressors installed on a single tank.

Their capacity can go up to 70 cfm, and pressure can go up to 175 psi.

Duplex units are bigger than single and multi-stage units.

However, it has a lower pressure compared to the two-stage compressor.

Lubrication is thus important for most reciprocating compressor units, although there are models with oil-less options.

Unlike the rotary screw compressor, this one is not intended for continuous use.

As for the size, reciprocating compressors are smaller compared to rotary screw compressors.

Most units are about 10 horsepower.

As such, you might find reciprocating compressors at workshops, garages, small businesses, and construction work.

Rotary vane compressors operate on a principle similar to that of a rotary screw compressor.

But instead of helix rotors, it uses vanes to compress air entering the activity.

It is also oil-cooled, just like the rotary screw compressor.

The unit has a cylindrical rotor placed inside a housing.

The rotor features a few slots inside where the vanes are placed.

It is placed in such a way that it almost gets entangled with the housing.

As such, the air is reduced in volume and pressurized by the rotating movement of the rotor.

Applications include, among others, sterilization of medical instruments, operating diverse tools, and drying products.

One advantage of a rotary vane compressor is its ease of maintenance.

You only need to apply a small amount of oil for lubrication.

Rotary vane compressors are also a lot simpler in design compared to reciprocating compressors.

Rotary compressors have fewer moving parts, unlike reciprocating compressors, which are more complex machines.

More moving parts mean increased risks of malfunction as more parts can fail to move.

It is typically measured as a percentage.

Maintenance is also important.

Aside from replacing oil, other maintenance tasks involve cleaning out the air filters and oil filters.

You may also have to replace both filters at a certain point, especially after prolonged use.

The good news, though, is that none of the aforementioned components are expensive.

These parts are also easy to find or buy and replace.

Scroll Air Compressor

A scroll air compressor is another positive displacement compressor ideal for light-duty applications.

It has two main components a stationary scroll and another that moves.

The moving scroll is rotated at an angle of 180 degrees.

Precisely machined, both scrolls form part of an involute spiral.

Both are bounded by a cover and a flat base.

Movement of the scroll creates suction, drawing gas from inlet openings.

It then reaches the middle of the assembly, wherein the pressurized gas is discharged through a port.

Scroll compressors are valued for being reliable and low maintenance.

It has few moving parts, which make it easier to maintain.

It also tends to run quieter compared to other compressors, particularly piston compressors.

The absence of inlet or discharge valves that generate noise contributes to this.

Scroll compressor operation is also known for being smooth and vibration-free.

Scroll compressors are widely used in industrial applications.

These units are best for air-conditioning applications.

These are also used in truck transportation and food refrigeration.

When selecting or buying a scroll compressor, youll have to choose from a single-phase and three-phase motor.

Your decision would be based on the key in of electricity connection available.

Next, you must consider the various pressure and flowrate considerations.

This handy and versatile tool is a fixture in a handymans toolbox.

It is not only portable but easy to carry around and store in any part of your home.

Air compressors are best used in inflating balls and tires, while pancake air compressors are utilized in airbrushing.

This punch in of air compressor is powered by either gas or electricity.

An electric air compressor can operate on standard household voltage.

This kind of air compressor wont emit fumes and thus best for indoor applications.

The downside is that this air compressor key in emits fumes and should only be used outdoors.

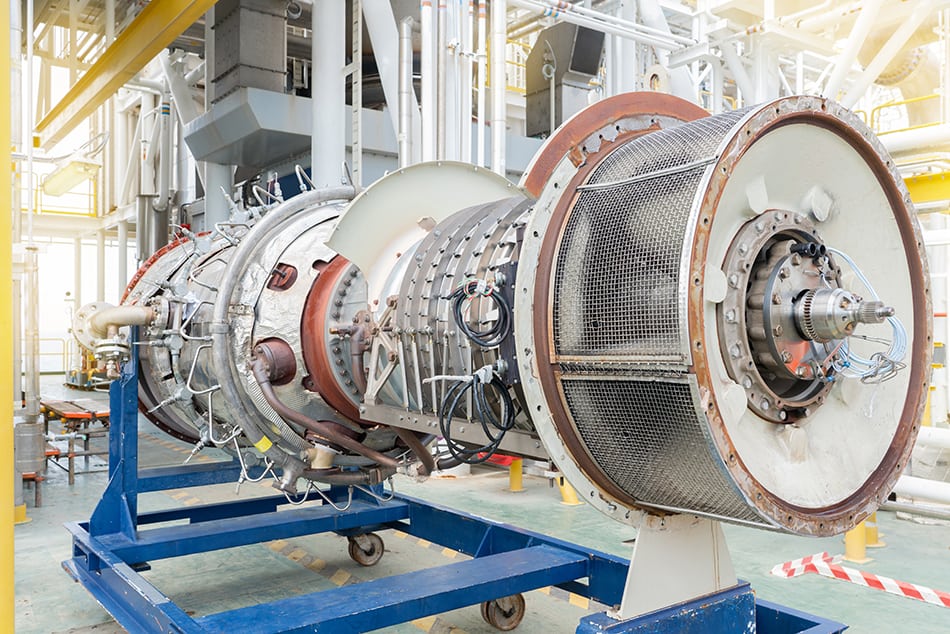

And because of that, axial compressors work under constant pressure, unlike their displacement counterparts.

Their operations are affected, too, by changes in external factors like inlet temperature.

Axial compressors are used in industrial applications such as aircraft propulsion and electricity generation.

As their name indicates, axial compressors dont change the direction of air.

The gas remains axial.

It enters and exits the compressor in an axial direction and parallel to the axis of rotation.

The air is accelerated and diffused so that the pressure is increased.

Axial compressors are small and light but surprisingly operate at high speeds.

These result in better fuel efficiency.

Centrifugal/Radial Air Compressor

The centrifugal or radial compressor is another pop in of dynamic compressors.

The centrifugal force draws the air towards the middle, increasing pressure and production of kinetic energy.

Each stage contributes to the overall increase in pressure.

Multi-stage utility is typically used in industries such as oil and gas production.

Centrifugal compressors are widely used in industrial applications.

For environmental applications, centrifugal or radial compressors are harnessed for drying, aeration, and wastewater treatment.

In the textile industry, centrifugal compressors are utilized for various applications ranging from drying to dust extraction.

The same goes for dust extraction, which is a vital process in the wood industry.